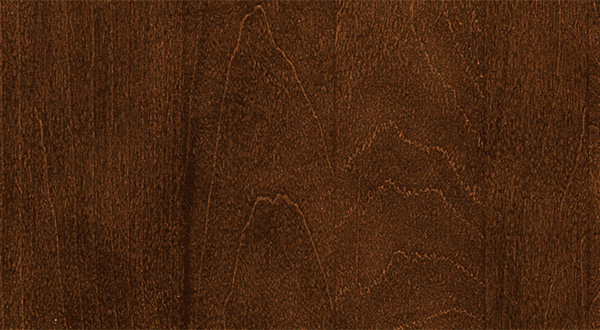

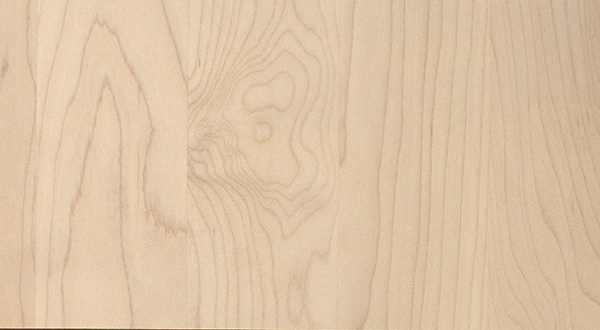

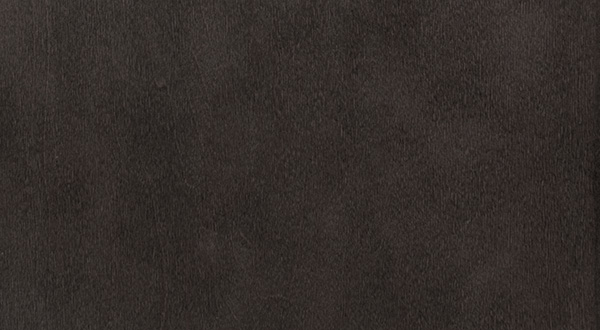

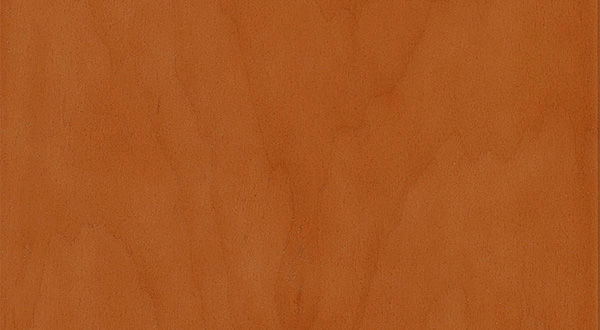

Inspiration Gallery

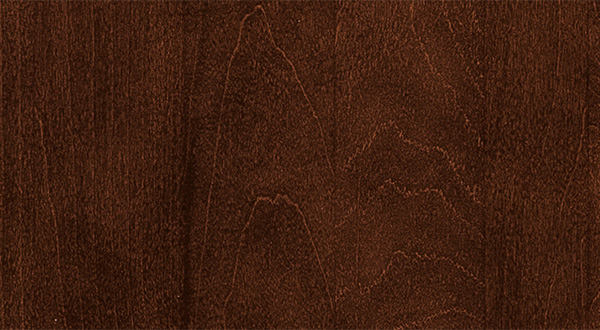

This gallery features our color collection for each of our product lines. You will see that stain colors will look different on the various species. Please note that the colors shown here are not going to appear accurately because of the variations of computer screens and devices. Make sure to order a sample for an accurate color representation. Custom color matching is available. See our finishing techniques for more clarification on our finishing options. *Refers to a wipe stains.

Material Type

Wood Finish

Wood > White Maple